3d printer clog cause

Make sure the belts have proper tension. Many 3D printers have a filament drive gear that uses a tiny set screw to hold it in position on the motor shaft and those can loosen and slip over time again causing inconsistent feed.

How To Clean A 3d Printer Nozzle Top 3d Shop

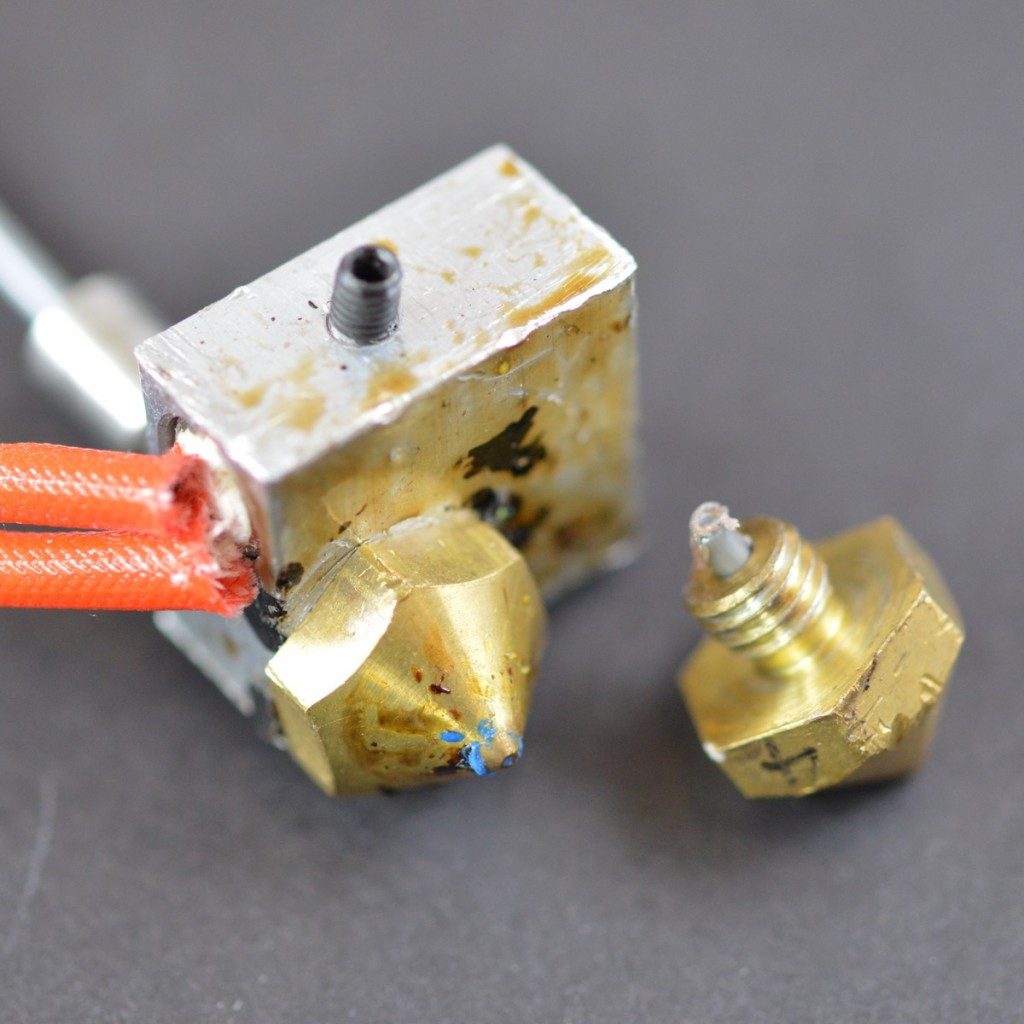

Cheaper filler and unintended contaminants lurking inside the material can build up or outright clog inside the nozzle at random intervals.

. Incorrect temperatures can cause the wire to harden abnormally which will have more difficulty being extruded. Burning of dirt can happen in a dirty environment such as a workshop where wood stone or dust is swirling around. There is an easy way to check the quality of extrusion consistency with the filament that youre using.

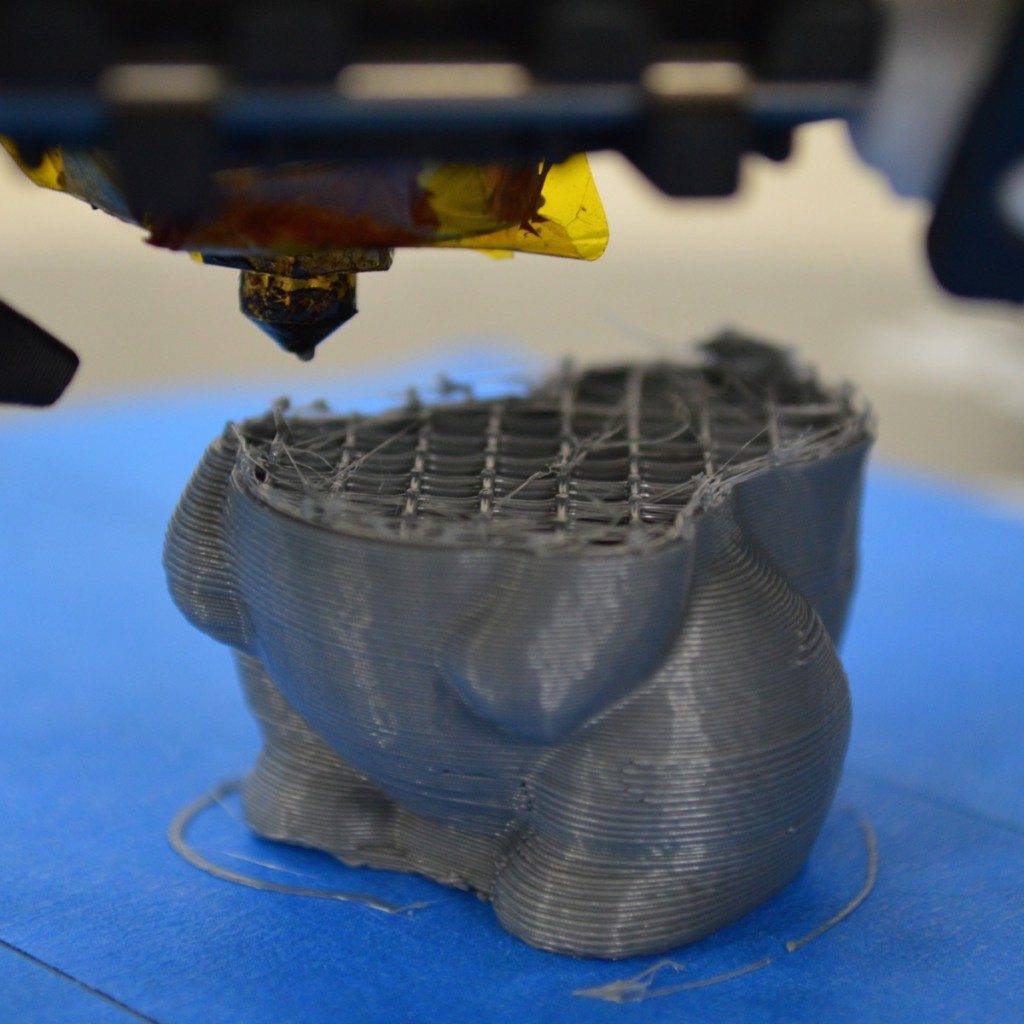

Obviously this will vary across different 3D printer and extruder models. When you use the 3d printer for a long time without regularly cleaning the nozzle it is very likely that your nozzle will become clogged. It can also be because of twisted filament or the temperature is too low or the printing speed is too high.

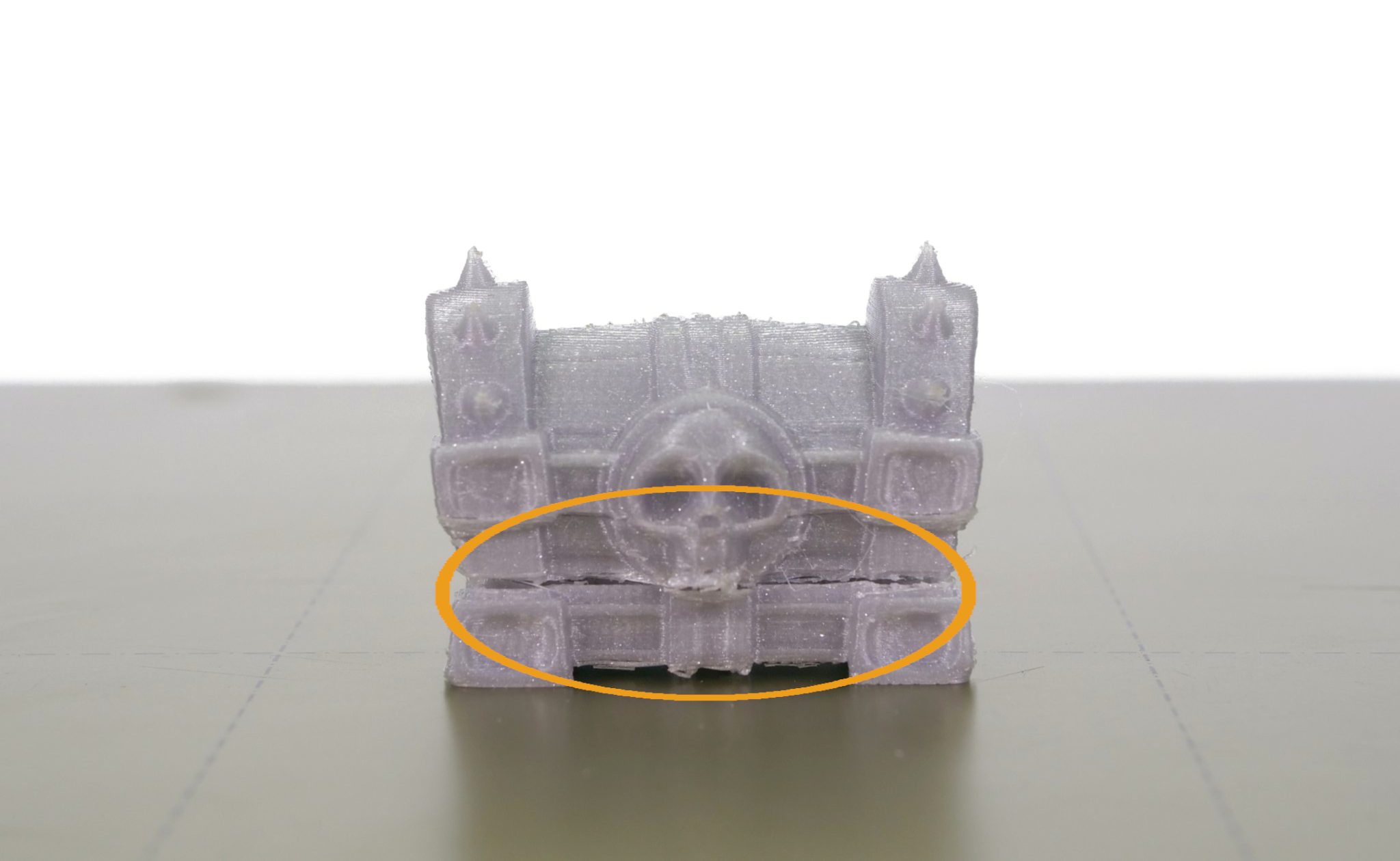

Andrew Lindseys suggestion about checking that the fan is running to prevent thermal creep up the feed path also should be part of checking the feed path. This may be due to a partial or fully clogged nozzle the nozzle being too close to the print bed low extrusion temperature entangled filament a problem with the PTFE tubes incorrect tension in the idler spring or simply because you are trying to push the printer beyond its capabilities. Clogged nozzles are also a very common cause of stringing.

Over-extrusion Misconfigured Z offset value Extruder assembly problems loose belts worn-out gears etc Filament problems moisture lousy quality etc. If the printing temperature of your 3D is too low for the filament you are using to print then the filament might not melt when it gets to the hot end. The most common reasons for your Ender 3 extruder to click or skip is the bed level clogged or damaged nozzle temperature setting slicer settings and extruder damage.

Clogged nozzle not only causes stringing but also many other serious errors that affect the quality of 3d prints such as under extrusion. This stress is greatest at corners where two sides meet. The quicker the cooling occurs the greater the stress on the object.

One reason why you may notice your extruder clicking is if the nozzle of your 3D printer is clogged. These clogs are mainly due from. Finding that your 3D printer nozzle keeps clogging.

Dirty filament that drags inside grains of dust which kneading with the plastic forms lumps larger than the exit hole. The blockage can be caused by burning dirt or filament especially with a small nozzle. A few distinct factors can cause your 3D printer to print rough surfaces which we have listed below.

A 3D printer warping problem typically occurs when an object is cooling unevenly after printing. To fix this problem inspect your printers motion system. When filament reaches the hot end it begins to melt.

3D prints may keep failing at the same point because the temperature falls so the filament isnt released or because of an uneven bed. This results in slippage which causes the layers to shift. Its likely down to poor quality filament.

Cooling as you know causes contraction and this contraction causes stress along the objects lateral surfaces. Like all mechanical parts the pulleys and belts of a 3D printer may start to slack overtime. Then it is melted by the heat.

A rule of thumb in setting the retraction distance is not to set it higher than the distance between the extruder and the nozzle. Your 3D printer cannot extrude the filament properly because of a clogged nozzle or uneven filament diameter. If your extruder is clicking you should immediately address the issue to avoid further damage to your machine.

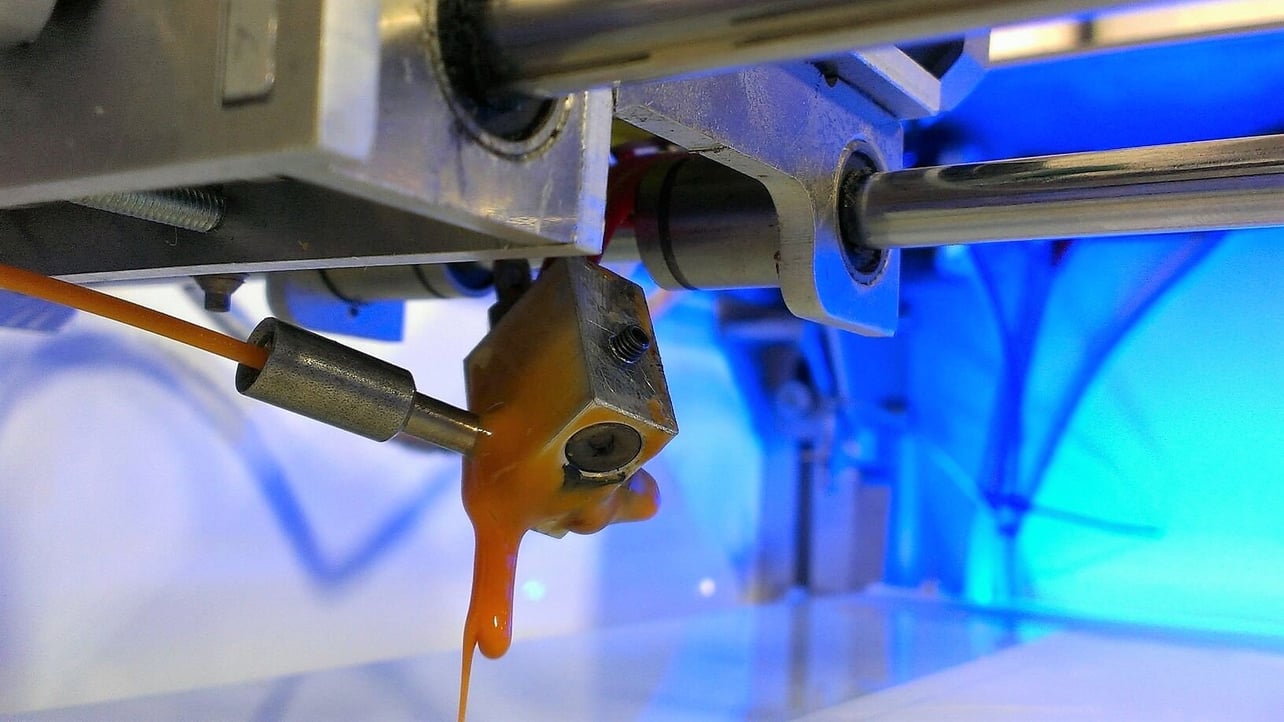

One of the reasons is loose printer pulleys and belts. When this happens the extruder assembly gets highly pressured because the filament cant flow freely in the nozzle as the nozzle is clogged. Therefore make sure the printer is in a clean.

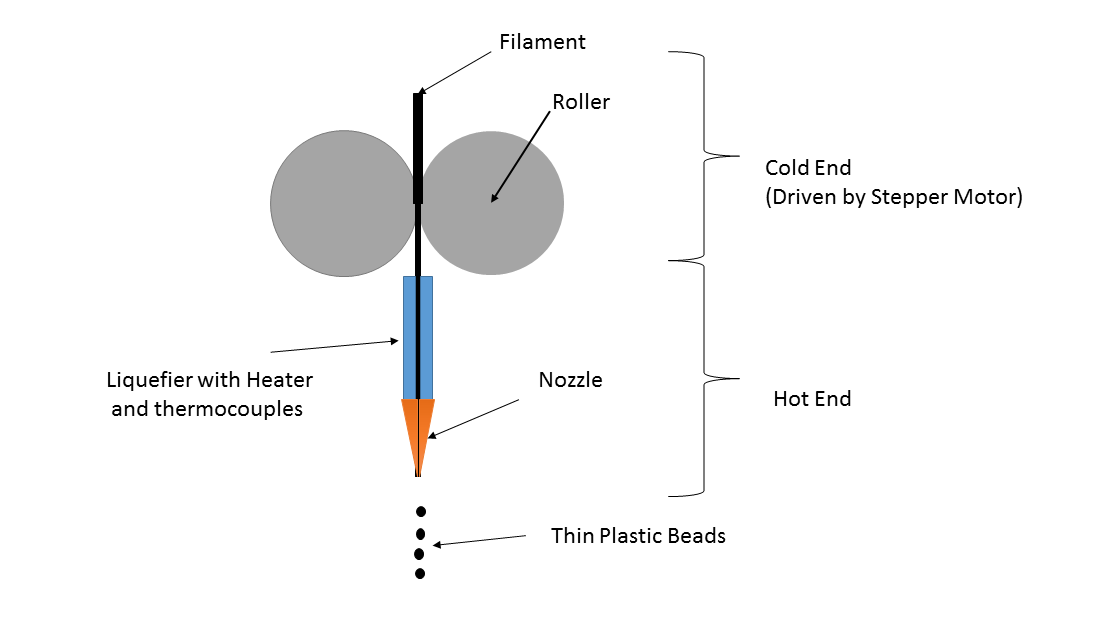

Filament passes through the extruder. This function is called retraction. If a part isnt secure the filament can find its way to the heat-breaker area.

Its logical that specks of the filament will be left behind. However the extruder gear can also turn the other way and pull filament back. Additionally the fan may be turning on at the same spot so the filament clogs at the hot end.

Worse retracting too much filament can cause deformation inside the extruder assembly which can result in a clogged nozzle. When your 3D printer is extruding material the extruder gear pushes the filament outwards.

Clogged Nozzle Hotend Mk3s Mk2 5s Prusa Knowledge Base

The Definitive Guide To Solving 3d Printing Problems By Bitfab Bitfab

How To Clean A Clogged 3d Printer Nozzle 3d Print Guides

Nozzle Clogging Vs Hot End Oozing What S The Difference All3dp

How To Clean A Clogged 3d Printer Nozzle 3d Print Guides

How To Clean A Clogged 3d Printer Nozzle 3d Print Guides

How To Clean A 3d Printer Nozzle The Easiest Ways All3dp

5 Causes Of A 3d Printer Nozzle Jam How To Fix It Pinshape 3d Printing Blog Tutorials Contests Downloads

How To Clean 3d Printer Nozzles And Prevent Clogs

5 Tips How To Prevent Clogging Of Your 3d Printer Youtube

Troubleshooting Jammed Hot End Airwolf 3d

5 Causes Of A 3d Printer Nozzle Jam How To Fix It Pinshape 3d Printing Blog Tutorials Contests Downloads

Basics Cleaning Out A Clogged Nozzle Tom S 3d Printing Guides And Reviews

3d Printer Troubleshooting Guide Clogged Nozzles Youtube

Help Nozzle Keeps Clogging After Some Time What Could Cause This R 3dprinting

Extruder Apparently Systematic Nozzle Clogging 3d Printing Stack Exchange

Is Your 3d Printer Nozzle Worn Out Sign Impact Causes How To Clean It 3d Print Schooling